Airflow Management in Focus: The Raised Floor11 min read

The 4 R’s are: the Raised Floor, the Rack, the Row, and the Room. Today, we’ll be giving a brief overview of the Raised Floor level.

What is Raised Floor Airflow Management?

Raised floor airflow management (AFM) refers to managing airflow through the horizontal plane of the raised floor, in which there are two main aspects to consider. The first, is sealing all openings in the raised floor other than supply tiles. The second, is managing the type, location, and number of supply tiles. Raised floor AFM ensures that the cooling capacity in the room is properly delivered to the cold aisle.

Raised floor AFM best practices include:

- Seal cable openings with brush grommets

- Seal openings around the perimeter of the room

- Seal openings in the perimeter walls below the raised floor or around partitions

- Make sure all supply tiles are properly located in front of IT equipment and remove any tiles that are not supplying cooling air to IT equipment

- Ensure supply tiles are the appropriate size in terms of % open area

Example: Raised Floor Grommets

Figure 1 shows several cabinets containing IT equipment intake air temperatures that exceed ASHRAE’s recommended maximum of 80.6° F (27° C). The cause of the hotspots is insufficient airflow from the supply tiles. Without enough conditioned air to meet the requirements of the IT equipment, hot exhaust air is flowing over the top of the cabinets.

Tile Management Considerations

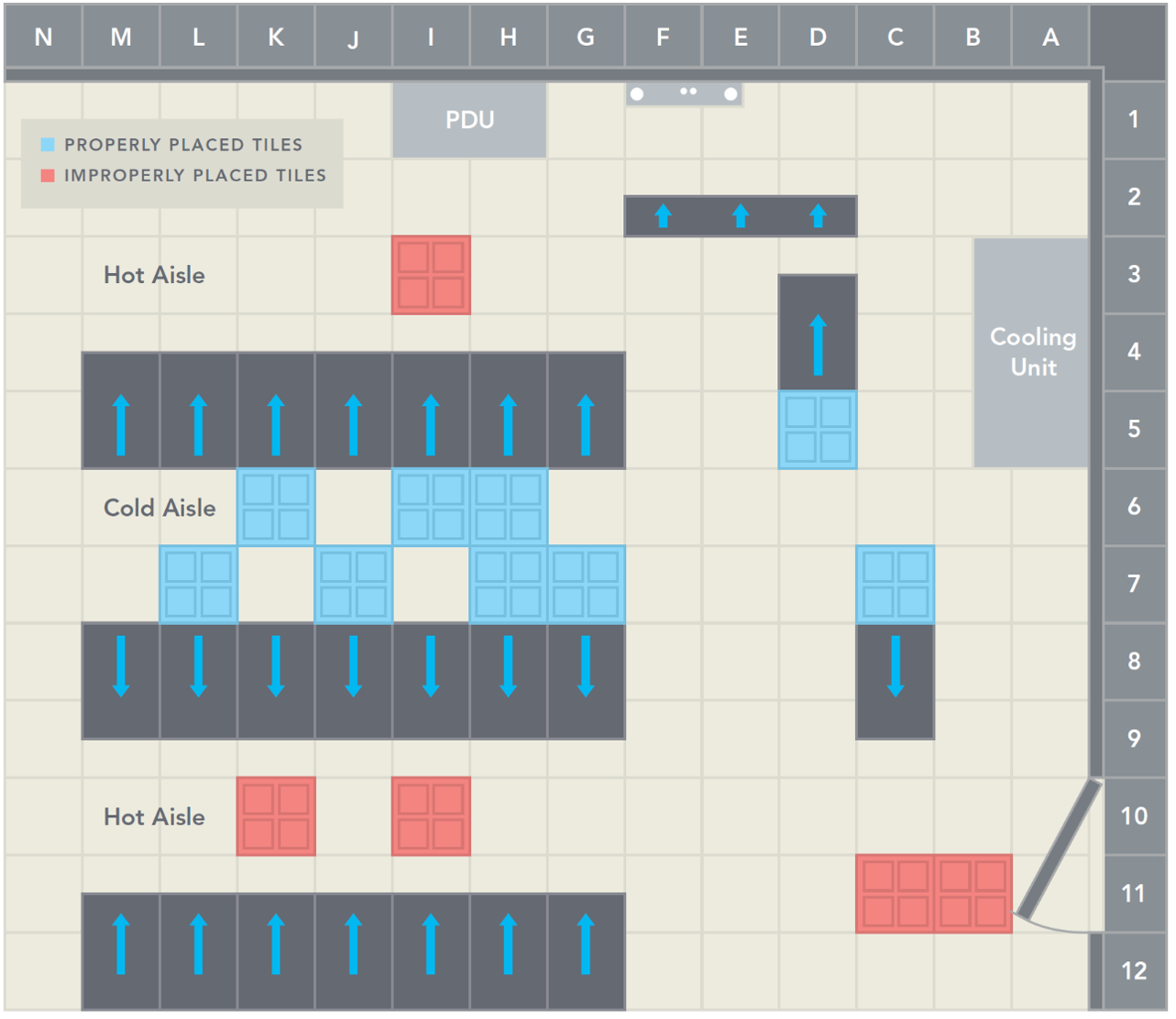

The goal of supply tile management is to provide the appropriate flow rate of conditioned air to meet the demand flow rate of the IT equipment. Supply tile management cannot be done in isolation, other integral aspects include: the number of cooling units running, cooling unit fans speeds, and the raised floor static pressure. With these aspects in mind, the variables directly related to supply tiles are the number of supply tiles in the cold aisle and supply tile placement (Figure 3), the open area of the supply tiles, and the opening of the dampers on supply tiles, if present.

Expert Advice

Sealing bypass open area of the raised floor is the best way to regain stranded cooling capacity, as it forces all the conditioned air through the supply tiles where it is needed. This enables the reduction of fan speeds and/or the ability to turn off cooling units.

After making AFM improvements at the Raised Floor level, it is important to make adjustments to cooling unit controls at the Room level to optimize the cooling infrastructure and realize energy savings. This is referred to as cooling optimization.

Featured Resources

- [Blog] Grommets: The Foundation of Cooling Efficiency in Raised Floor Data Centers

- [Blog] Perforated Tile Placement: Why the Right Location Matters

- [Blog] Airflow Management Considerations for Raised Floor vs. Slab Floor Environments

- [Report] ASHRAE®-Published Report Finds that KoldLok® Brush Grommets Seal Best, Save the Most Energy

- [White Paper] 6 Reasons to Specify Air-Sealing Grommets in the Design of a New Data Center

0 Comments