Three Key Places that are Killing Data Center Efficiency17 min read

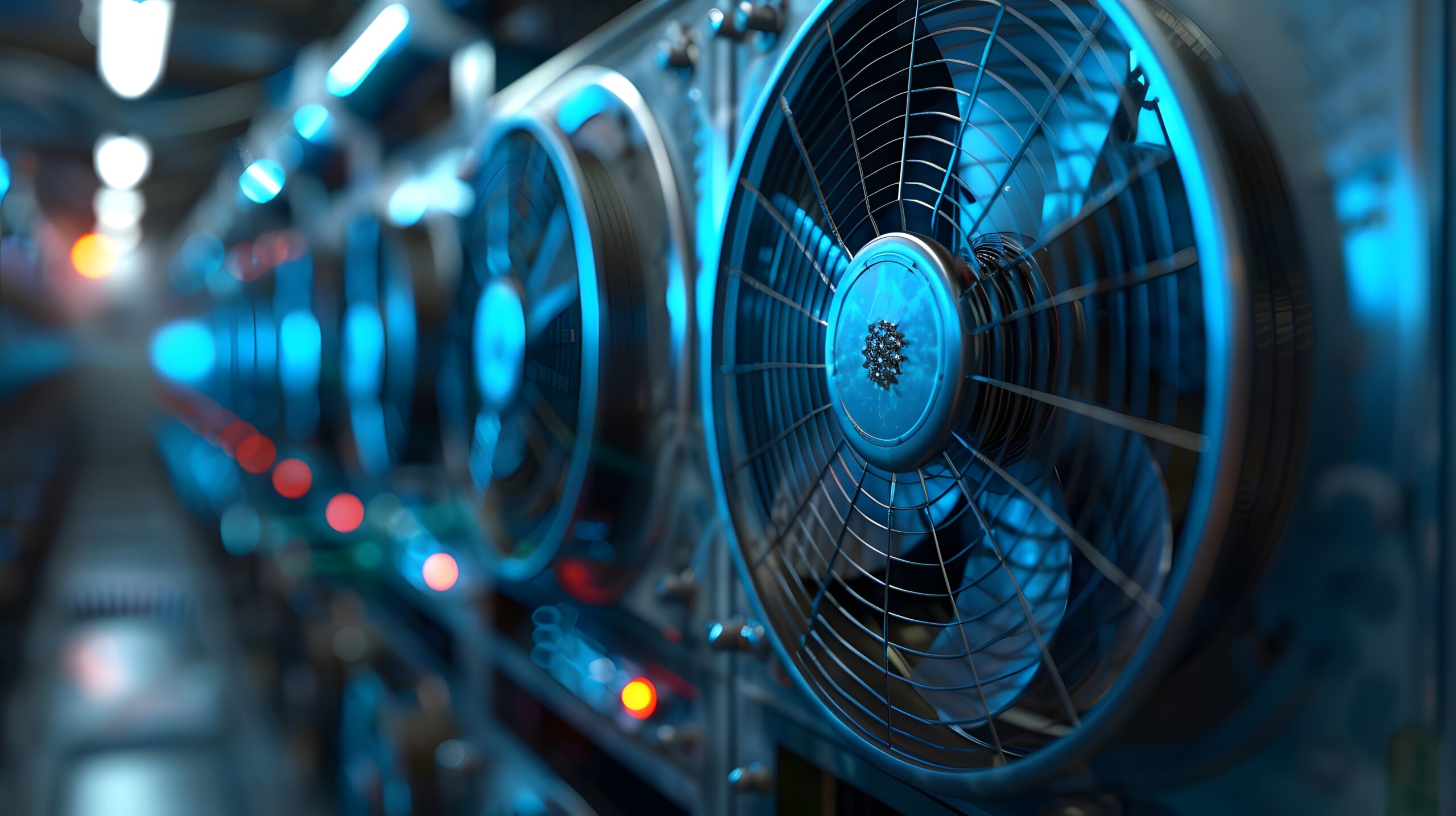

Organizations are spending big these days on cooling infrastructure. They are upgrading their cooling systems to cope with the heat generated by modern processors. Many are implementing liquid cooling in preparation for the rack densities demanded by AI applications. However, a close inspection of most data centers reveals that a good portion of this cooling investment is wasted. Why? By failing to pay attention to a few simple basics of cooling and airflow management.

Here are three key areas causing rampant cooling inefficiency:

Cable Openings

Think about the number of cables that run inside data centers. These cables enter racks from above, poke through raised flooring tiles, and snake from rack to rack and row to row. Data centers couldn’t operate without all these cables and wires. However, they also provide innumerable channels through which cold air can leak into the hot aisles (and hot air can flow into the cold aisles). Every point of mixing air lowers the efficiency or the cooling system and increases energy bills. In extreme cases, it can lead to severe hot spots and even equipment failure.

The solution is to use specially designed grommets at every point of cable penetration. These grommets are used to seal new or existing cable penetrations. They are typically made of a plastic frame that holds durable nylon brushes. The cabling passes through the brushes easily yet provides a seal that prevents air from escaping. Grommets come in a wide range of circular, square, rectangular and customer shapes to fit all cabling requirements.

They are designed to seal openings in new and existing raised floor cutouts to block bypass airflow and maximize cooling system efficiency. Some are designed with a split frame which allows for installation or removal without disturbing cables and contains no loose or partially fastened parts.

Rack Openings

Rack configurations vary from data center to data center. What goes into those racks is subject to frequent change. Some are jammed with servers, while others may have room for more equipment. As a result, there are often gaps left in the front or the back of racks. In some data centers, as much as 48% of conditioned air might be wasted due to spaces in racks, and gaps in flooring or made by cables.

The time-honored solution here is blanking panels. Yet this simple solution is an area that many data centers neglect. Blanking panels are composed of flat pieces of metal or plastic that fit across the front or back of a rack. Some are the same size as the front or back of a server, others can be 2U and some panels cover a large portion of an entire rack. As with grommets, they keep hot and cold air separate. They are easy to remove when new equipment is being added to the rack.

Their presence is key in preventing hot exhaust air from recirculating into cold aisles and vice versa. If recirculation is occurring, fans will compensate by running faster and air handlers will run longer and consume more power.

Blanking panels are designed to effectively seal openings in IT equipment cabinets and control airflow for optimized cooling effectiveness. They help by reducing hotspots and bypass airflow to prevent equipment exhaust air from migrating to the conditioned air intake stream at the front of the cabinet.

Non-Contained Aisles

Containment is the use of partitions and panels to effectively separate the cold supply air from the hot exhaust. It directly improves data center thermal management, thereby creating a more predictable and efficient operating environment.

As each data center is different, containment solutions must be adaptable to fit any and all configurations. Sometimes, large panels that extend high above the racks are enough to achieve a good level of separation. This approach is often used to channel the hot air from the back of the racks to the AC return or upward to a drop-ceiling void.

But the highest level of efficiency is done by completely enclosing the rack with horizontal and vertical panels as well as doorways to allow technicians to enter. However it is done, cold air containment is there to isolate cooling air from hot air and feed it directly to the intakes of critical equipment.

In cases where full containment isn’t feasible, modular containment is an option that incldues horizontal and vertical panels and various kinds of doors designed for tool-less installation, removal, and re-installation. They can contain either the hot or cold aisle and are applicable to new builds and retrofit data centers.

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

Drew Robb

Writing and Editing Consultant and Contractor

0 Comments