Modular Cold Aisle Containment and Legacy Cold Aisle Containment: A Comparative CFD Analysis9 min read

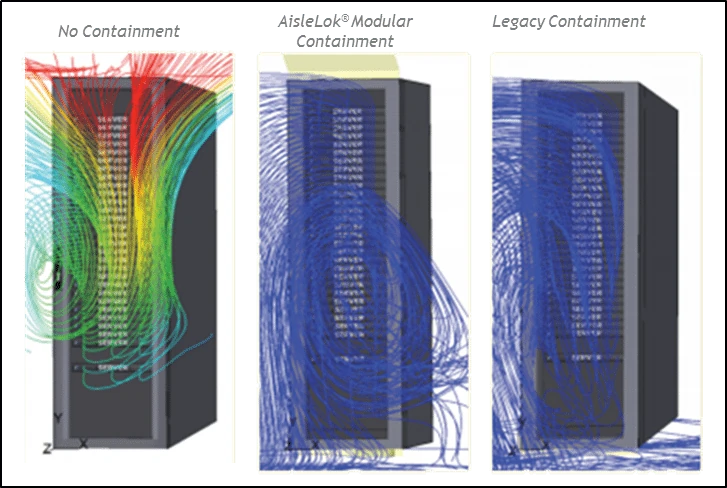

Last year, Upsite Technologies introduced the first-ever ‘modular’ containment system to the market, AisleLok® Modular Containment. Many operators were intrigued by the unique design, as no one had previously seen a containment system with an open architecture. But as with many things in life, appearance isn’t everything. Though the open architecture of AisleLok® appears counterintuitive, it was specifically engineered to effectively separate the cold supply air from the hot exhaust air with a minimum of materials, while being extraordinarily easy to install, limiting obstructions to fire suppression and providing flexibility for relocation.

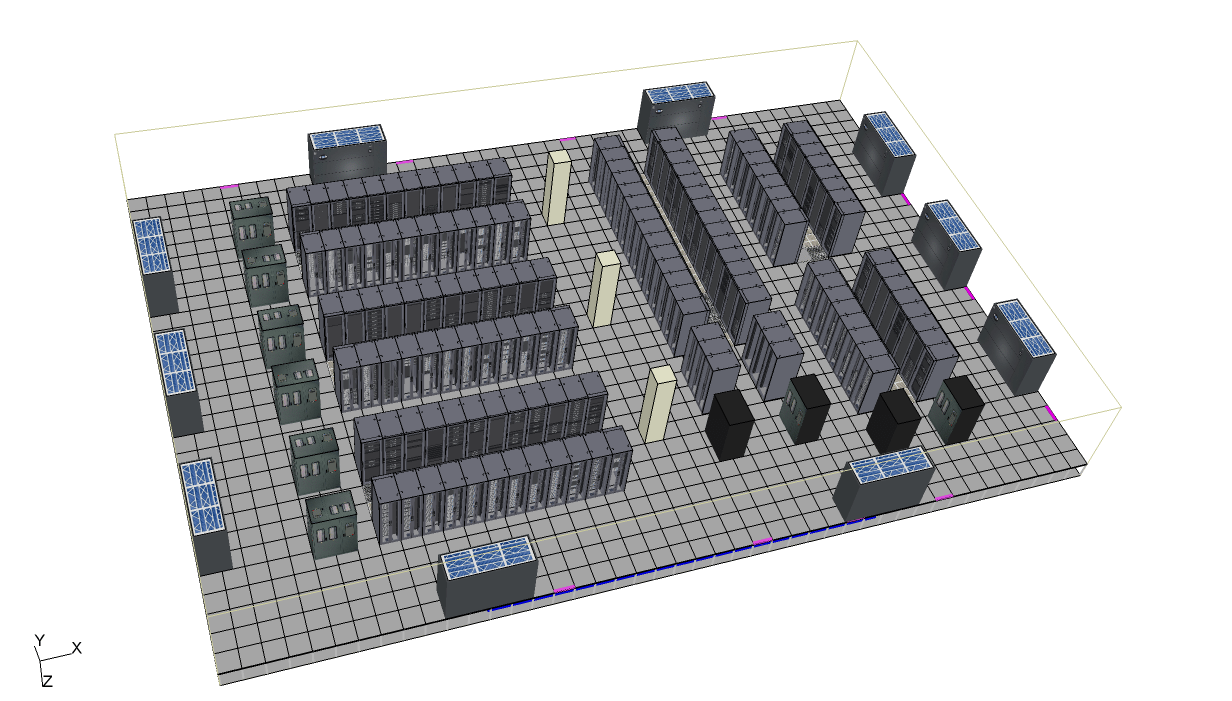

But beyond these unique features, we wanted to thoroughly examine how our new AisleLok® solution stacked up against the more traditional legacy containment systems, so we set out to do some research. We created a CFD model using Future Facilities’ 6Sigma software and laid out a typical 5,280 Sq Ft Data Center. We then analyzed the conditions using 3 distinct approaches: Approach 1 had No containment (the base line), Approach 2 had contained cold aisles using AisleLok Modular Containment, and Approach 3 had contained cold aisles using a legacy containment system. Here’s what the CFD results revealed, as fully explained in our new white paper.

Fig 1: Baseline Model of Data Center at 5,280 Sq Ft (490 Sq M)

Temperature Reduction

Both forms of cold aisle containment had a significant impact on the cabinet inflow air temperature. For mid-row cabinets, AisleLok Modular Containment reduced the cabinet air inflow temperature from 85.9°F (29.9°C) down to 67.3°F (19.6°C). The legacy containment system reduced the air inflow temperature down to 63.3°F (17.4°C), a delta of only 3.5 F° (2.2°C). This showed that both AisleLok Modular Containment and legacy containment allowed for significant inflow temperature reduction.

Airflow and Cooling Reduction

Once IT equipment intake air temperatures were reduced, fan speeds were reduced to realize operational cost savings. Again, both forms of containment allowed for a significant reduction in cooling airflow rate compared to no containment in the cold aisle. AisleLok Modular Containment enabled a 30% reduction in airflow to the raised floor without IT equipment intake temperatures exceeding the ASHRAE recommended maximum temperature of 80.6F° (27°C). Legacy containment performed slightly better, allowing for a 35% reduction in airflow to the raised floor.

Energy Savings

Energy savings is often a major motivator for data centers to install a cold aisle containment solution. As expected, both forms of containment yielded significant savings. Assuming a $.10/kWh energy cost rate, AisleLok Modular Containment yielded an annual energy savings of about $32,000—a substantial amount of savings for such a simple installation. Legacy cold aisle containment provided slightly more annual energy savings, at about $35,000.

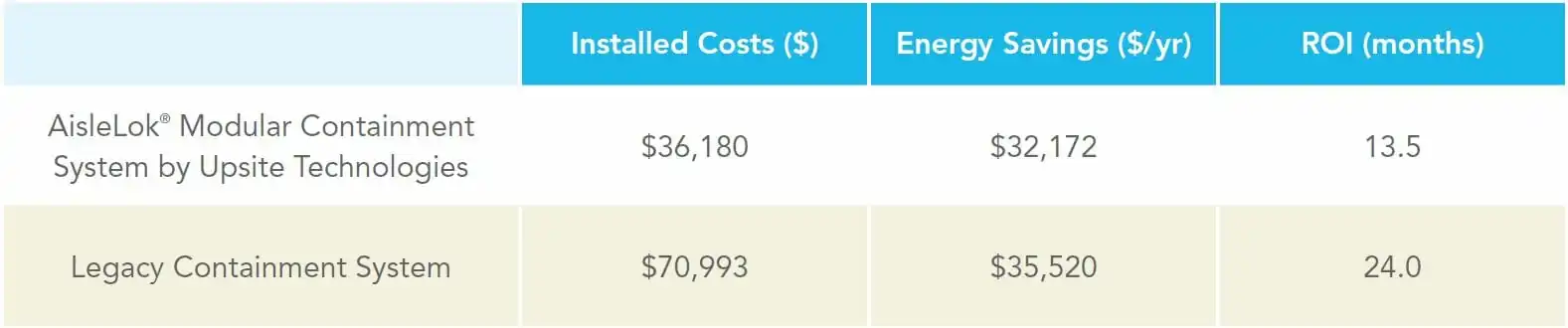

ROI & Total Cost of Ownership (TCO)

This is a biggie, and quite frankly where the divide between the two solutions becomes more apparent. Because AisleLok Modular Containment attaches with magnets and requires zero customization, it can be installed by internal staff in a very short amount of time, which saves the costs of having a 3rd party come out to measure, design, and install a solution. The ordering and installation of Full containment requires many man hours that end up inflating the higher product cost . Because of this, the ROI difference between the two was significant: AisleLok Modular Containment can pay for itself in about 13.5 months, while legacy containment takes at least 24 months to fully pay for itself. The chart below elaborates on this:

*Cost estimates are based on full installation of the computer room configuration in section 2.2 of the white paper. The model features 138 IT cabinets and measures 5,280 ft² (490m²).

*Cost estimates are based on full installation of the computer room configuration in section 2.2 of the white paper. The model features 138 IT cabinets and measures 5,280 ft² (490m²).

The spread is even greater if you consider changes that may need to be made to the containment system after installation. If additional cabinets are added to a row, for example, a legacy containment system will have to be reconfigured, which requires even more design and installation from 3rd parties. Conversely, AisleLok containment is modular, so you can move the Bi-Directional Doors yourself to the new outer-most rack, and add more Rack Top Baffles as needed.

Conclusion

When choosing a cold aisle containment solution, there are many factors to consider when determining which will work best for your situation. But if considering AisleLok Modular Containment vs a legacy containment system, it’s easy to see that the performance levels of the two are very similar. Each is effective at decreasing IT intake temperatures and enabling the reduction of energy costs. However, the benefit of modularity and self-installation give AisleLok the leading edge in many situations, especially when it comes to Total Cost of Ownership (TCO).

1 Comment

Submit a Comment

Airflow Management Awareness Month

Free Informative webinars every Tuesday in June.

*Cost estimates are based on full installation of the computer room configuration in section 2.2 of the

*Cost estimates are based on full installation of the computer room configuration in section 2.2 of the

Good Stuff