5 Common Myths about Data Center Containment9 min read

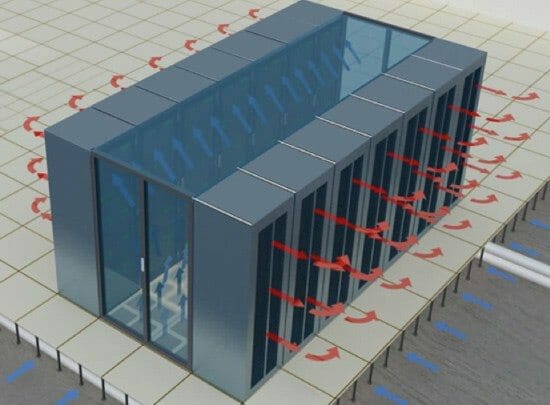

Various dynamics have been driving the adoption of containment as an air flow management (AFM) method. Some primary drivers include:

- The need to reduce operating costs by making the cooling infrastructure more efficient.

- The need to eliminate high IT equipment intake air temperatures.

- The need to increase the utilization of computer room space.

To prove this trend, a recent Uptime Institute study revealed that 78% of large data center operators have already deployed containment. However, a few prevailing misconceptions and half-truths still persist about what containment can provide.

The Myths

Myth #1 – Containment reduces (or even eliminates) bypass airflow.

This is mostly untrue. Containment reduces bypass airflow only if it reduces recirculation of exhaust air.

Bypass airflow, or the conditioned air that does not flow through IT equipment before returning to a cooling unit, is reduced only if the:

- Total air volume produced by the cooling units decreases.

- Air volume required by IT equipment increases.

Myth #2 – Containment alone can reduce operating costs.

Containment slightly reduces operating costs only if intake temperature reductions of IT equipment result in a drop of IT cooling fan speeds.

In most cases, there is little to no financial benefit from intake temperature reduction given that most IT intake temperatures fall below the 75 °F to 80 °F threshold where IT equipment fan speeds increase. Yet, containment does create conditions where you can achieve operating cost savings by reducing cooling unit fan speeds, turning cooling units off, raising cooling unit set points, or increasing chilled water set points. These savings can be substantial, but to attain them, you must make cooling infrastructure and control adjustments after containment installation.

Myth #3 – When containment is deployed, perforated-tile placement doesn’t matter.

Or it is often believed that you should place two full rows of perforated tiles in cold aisles. Containment prevents the mixing of conditioned air with hot exhaust air before entering IT equipment, but it does nothing to balance the total flow rate of conditioned air to the total flow rate required by IT equipment.

If more conditioned air enters a cold aisle than is required by IT equipment, the excess conditioned air will leave the aisle through small gaps or get pushed through the servers, even if the aisle is fully

contained. Any excess volume of conditioned air signifies wasted fan energy. Methods abound for balancing the volume of conditioned air when implementing containment—perforated tile numbers and type, damper positions, cooling unit fan speeds, number of cooling units running—but you must employ at least one of these methods for cost savings.

Myth #4 – Containment increases the return air temperature to cooling units.

This is untrue because the return air temperature is determined by the volume of air moving through the room, the IT heat load, and the cooling unit set point.

Cooling units work to maintain the set point (air return temperature to the cooling unit), unless supply-side control is in operation. It is possible for containment to result in portions of warmer air flowing back to the cooling unit, but the average temperature of all air flowing back to the unit will be the same. Containment does create an environment where you can raise both return and supply-side control set points, which will increase both unit capacity and efficiency.

Myth #5 – Full containment is essential; curtains and partial containment don’t work.

This myth typically generates from observing curtains “flapping in the breeze” or blowing out. It’s true that curtains or partial containment will not contain conditioned air as well as hard containment, but the problem is not the curtains or lack of full containment. There is excess conditioned air being supplied to the aisle, which is a state of deficient airflow balance.

When it comes to proper and effective AFM for your data center, there’s no “one-size-fits-all” method or magic solution—no matter what anyone tells you. Whether it’s containment or any other methods or products, AFM requires a measured, holistic, and verifiable approach. So beware the myths of AFM!

3 Comments

Submit a Comment

Airflow Management Awareness Month

Free Informative webinars every Tuesday in June.

The last myth, regarding partial vs. full containment, is most welcome. Too many people don’t recognize the improvements that partial containment can make.

Wish you had said something about Hot vs. Cool Aisle containment – namely that they can both be effective if implemented correctly, and that, like everything else, there is no single “right” solution for every project. But air flow balance with cool aisle containment is definitely more of an issue than with hot aisle. (Although it is, and always should be, an issue that just shows up more readily when a cool aisle implementation is done.)

Great points and I especially prescribe to the final comment that AFM does not have a 1 size fits all application. The entire envelope and subsets of airflow efficiency must be looked at. Blanking panels, floor grommets, cable management, rack alignment etc. etc. all contribute to the whole. And of course those pesky “People” who are in and out of the racks and room all day.

Thanks Tom, yes, there is definitely an organizational component to successful AFM. Some protocol and means of enforcement / consequences for not following protocol. Often there is simply a missing educational component.