Airflow Management in Focus: The Room15 min read

With so many variables affecting airflow within a data center, it can be daunting to know where to start and how to get the most out of airflow management improvements. The 4 R’s of Airflow Management™, developed by Upsite Technologies, is a holistic methodology for identifying and implementing changes to optimize the data center’s cooling infrastructure and realize energy savings.

The 4 R’s are: the Raised Floor, the Rack, the Row, and the Room. Today, we’ll be giving a brief overview of the Room level.

What is Room Airflow Management?

Room airflow management (AFM) refers to the optimization of the cooling infrastructure and is the only way to realize energy savings from AFM improvements made at the Rack, Raised Floor, and Row levels. This is referred to as cooling optimization.

Room AFM best practices include:

- Raising cooling unit air temperature set points as high as possible without exceeding the maximum allowable IT equipment intake air temperature

- Reduce fan speeds for units with variable frequency drives (VFD) as much as possible without exceeding the maximum allowable IT equipment intake air temperature

- Expand the allowable relative humidity (Rh) band to prevent cooling units from “fighting” with each other (wasting energy by one unit trying to dehumidify while another unit tries to humidify)

- Turn off excess cooling units when possible

Example: Bypass Airflow

Bypass airflow is any conditioned air from a cooling unit that does not pass through IT equipment before returning to the cooling unit. The total volumetric flow rate of conditioned air through cooling units is independent of the volumetric flow rate of air through IT equipment.

- Bypass airflow (cfm) = Total cooling flow (cfm) – Total IT equipment demand flow (cfm)

Bypass airflow is costly because of the fan energy required to move the air around the room and the reduced efficiency of the cooling equipment due to lower return air temperatures.

- The best way to reduce bypass airflow is to first improve AFM and then reduce cooling unit fan speeds or turn off cooling units

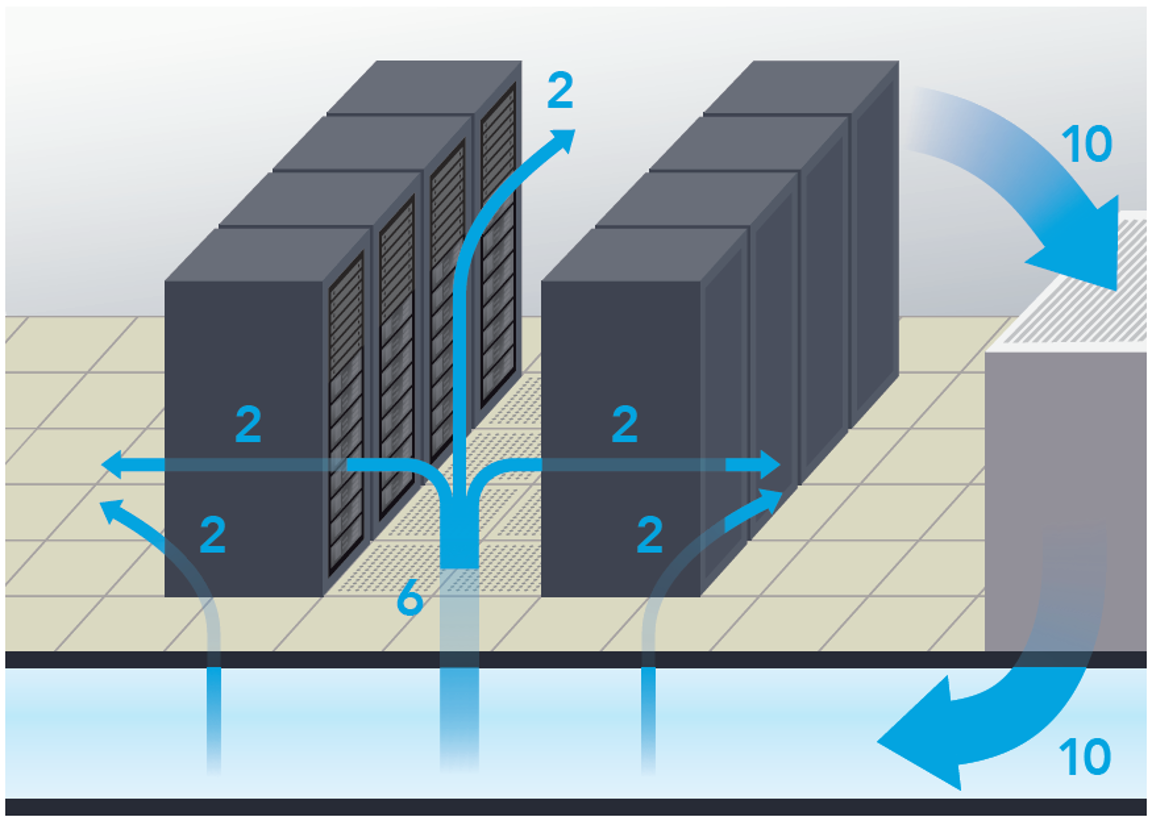

Figure 1 below shows typical airflow patterns before airflow management and cooling optimization.

Figure 1: Typical airflow patterns before AFM and cooling optimization

- The total flow rate of conditioned air through all cooling units is 10

- Therefore, the total flow rate of conditioned air flowing out of the raised floor is 10

- There are 4 units (2+2) flowing out of unsealed cable openings

- There are 6 units flowing into the cold aisle

- The IT equipment only requires a total of 4 units (2+2) of conditioned air

- 2 units of conditioned air leave the cold aisle as bypass airflow

- With the 4 units of bypass airflow from unsealed cable openings, there is a total of 6 units of bypass airflow

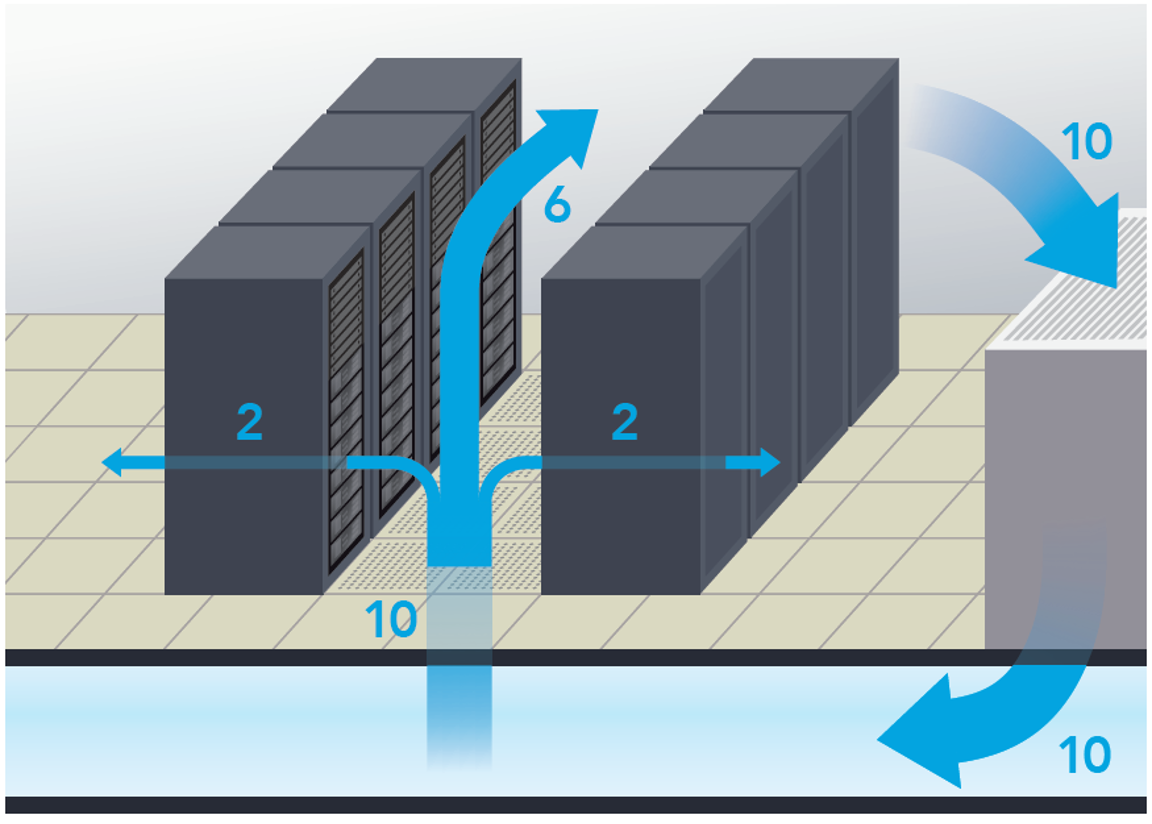

Figure 2 below shows typical airflow patterns after airflow management, but before cooling optimization.

Figure 2: Typical airflow patterns after AFM but before cooling optimization

- By sealing all the cable openings, the full 10 units of conditioned airflow is being supplied into the cold aisle

- The IT equipment still only requires a total of 4 units (2+2) of conditioned air

- 6 units of conditioned air leave the cold aisle as bypass airflow

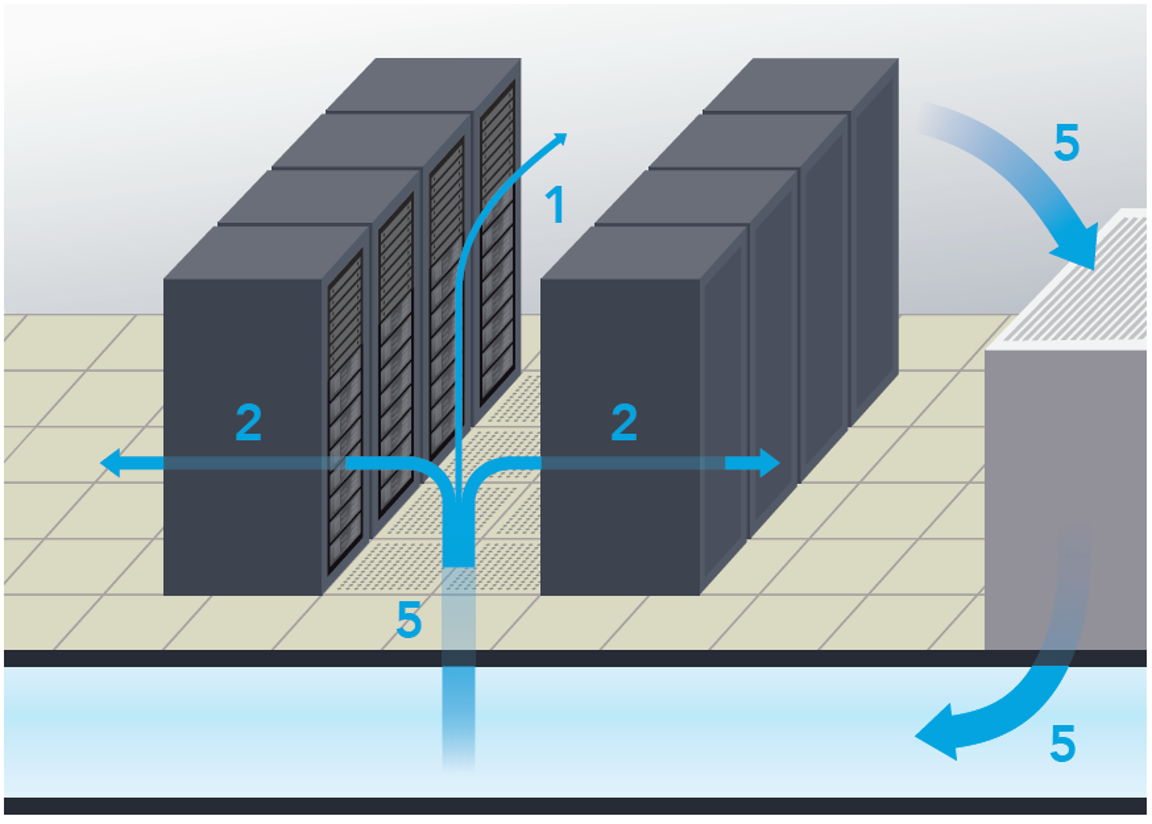

Figure 3 below shows typical airflow patterns after both airflow management and cooling optimization. This is where you optimize the cooling infrastructure to realize energy savings.

Figure 3: Typical airflow patterns after AFM and cooling optimization

- Now the flow rate of conditioned air through cooling units can be more closely matched to the total flow rate through the IT equipment

- Conditioned airflow supplied by the cooling unit has been reduced by 50% (from 10 units to 5 units)

- This was achieved solely by reducing fan speeds

- 5 units of conditioned airflow are now being supplied into the cold aisle

- 4 units (2+2) of conditioned air are being supplied to the IT equipment as needed

- Bypass airflow has been reduced from 6 units to 1 unit

- The 1 unit of air is for redundancy

Expert Advice

After any significant airflow management improvement or IT load installation or removal, there’s an opportunity to evaluate Room level controls to ensure efficient operation and sufficient redundant capacity.

Once AFM best practices have been implemented effectively and adjustments have been made to the controls and set points, monitoring is mostly necessary for identifying failures in the cooling infrastructure as the IT equipment intake air temperatures will remain stable. Monitoring is also valuable for identifying significant adds, moves, or changes that were not formally communicated and planned for.

Featured Resources

- [Blog] What You Need to Know About Room Airflow Management

- [Video] Room Airflow Management Best Practices Explained

- [Video] What is Cooling Optimization?

- [Video] How the Four Delta T’s Impact Data Center Cooling Optimization

- [Blog] What Happened to Promised Airflow Management Efficiency Savings? – Part 1

- [Blog] What Happened to Promised Airflow Management Efficiency Savings? – Part 2

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

0 Comments