Airflow Management in Focus: The Row15 min read

With so many variables affecting airflow within a data center, it can be daunting to know where to start and how to get the most out of airflow management improvements. The 4 R’s of Airflow Management™, developed by Upsite Technologies, is a holistic methodology for identifying and implementing changes to optimize the data center’s cooling infrastructure and realize energy savings.

The 4 R’s are: the Raised Floor, the Rack, the Row, and the Room. Today, we’ll be giving a brief overview of the Row level.

What is Row Airflow Management?

Row airflow management (AFM) refers to improving cold aisle and hot aisle separation within the data center. After improving AFM at the rack and raised floor levels, evaluating the air distribution in rows is the next step in AFM and reducing energy consumption. This generally involves installing doors on either the ends of hot or cold aisles and baffles or a full roof over the aisle.

Row AFM best practices include:

- Block open spaces underneath racks to prevent air flowing under the cabinets

- Seal spaces in cabinet rows where there are missing cabinets or gaps between cabinets

- Install aisle end doors on either the hot or cold aisles

- Install top-of-rack containment (partial or full) on either the hot or cold aisles

Example: Hot Aisle and Cold Aisle Containment

There are numerous configurations for aisle containment, all of them rely on the foundation of hot and cold aisle alignment. In all cases the goal is to separate the cool supply air from the hot exhaust air. This only needs to be done in one location, it is not necessary to do both hot aisle containment and cold aisle containment.

Studies have proven that either hot and cold aisle containment are equally efficient if implemented thoroughly.

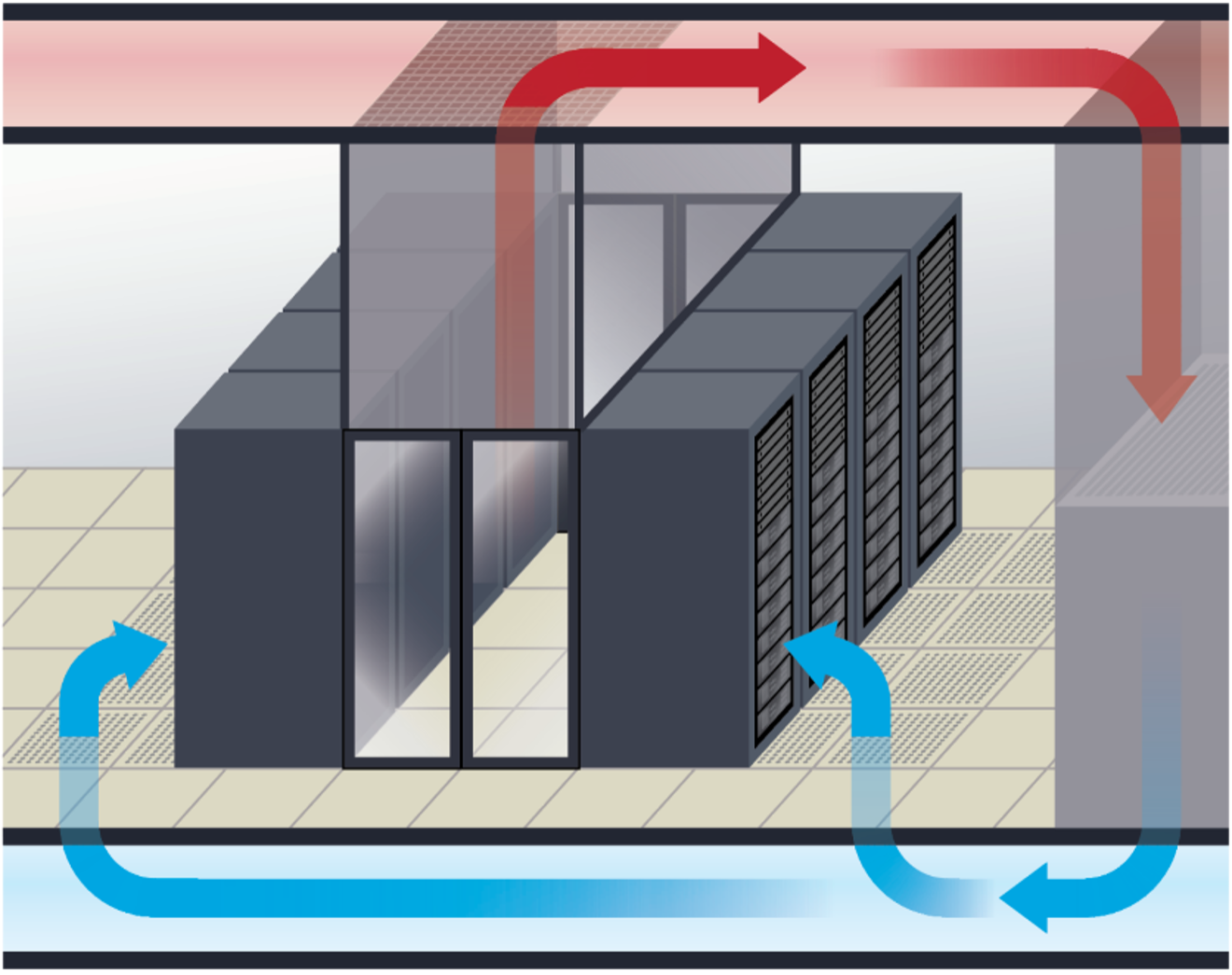

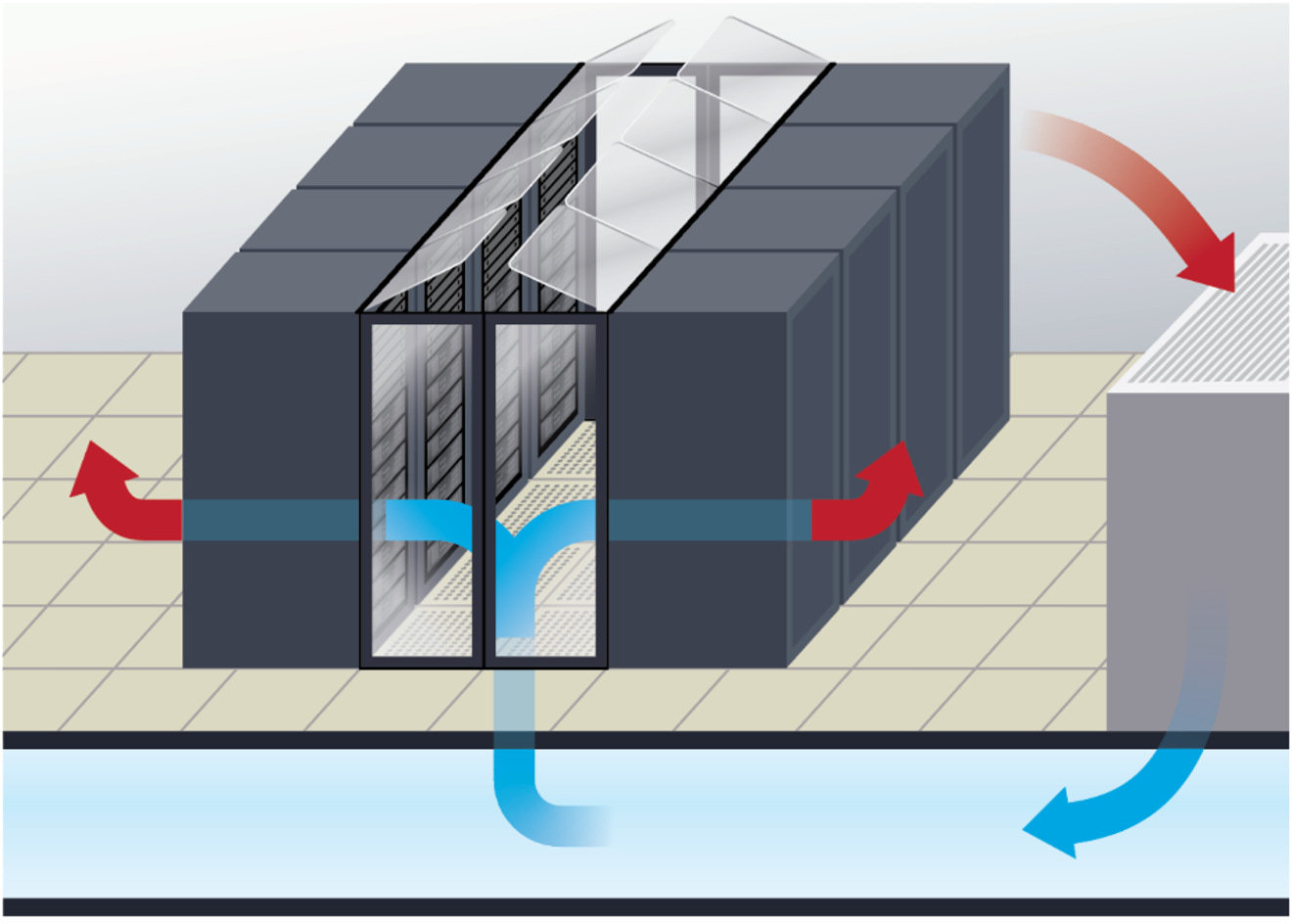

Figure 1 shows full hot aisle containment. In general, hot aisle containment is desirable because the rest of the room is left cool. However hot aisle containment requires a ceiling plenum or other means to duct the exhaust air back to the cooling units. Many rooms don’t have this option which is why cold aisle containment is more common.

Figure 1: Full hot aisle containment

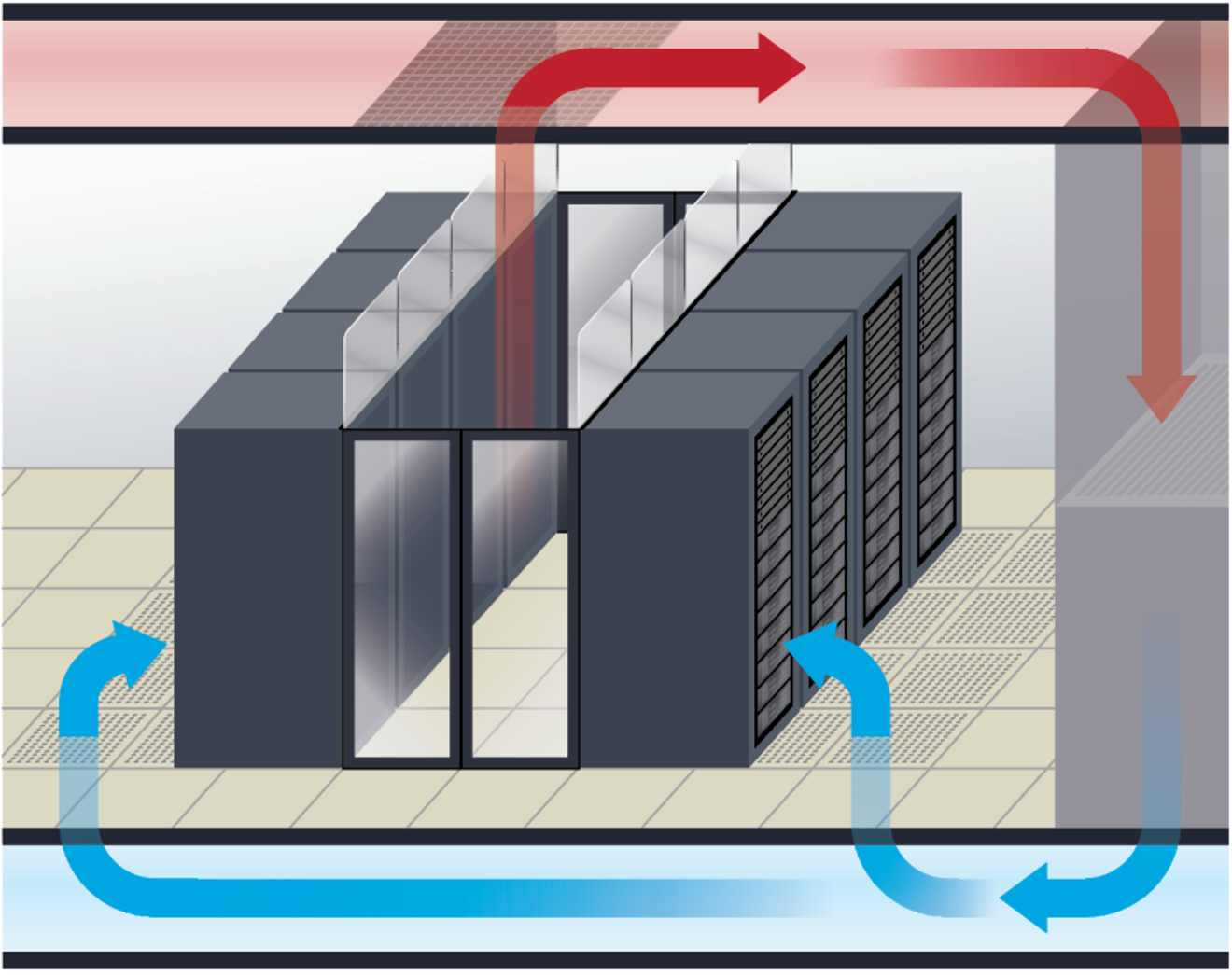

Figure 2 shows partial hot aisle containment. Baffles are used to direct the exhaust air to the grill openings in the ceiling plenum.

Figure 2: Partial hot aisle containment

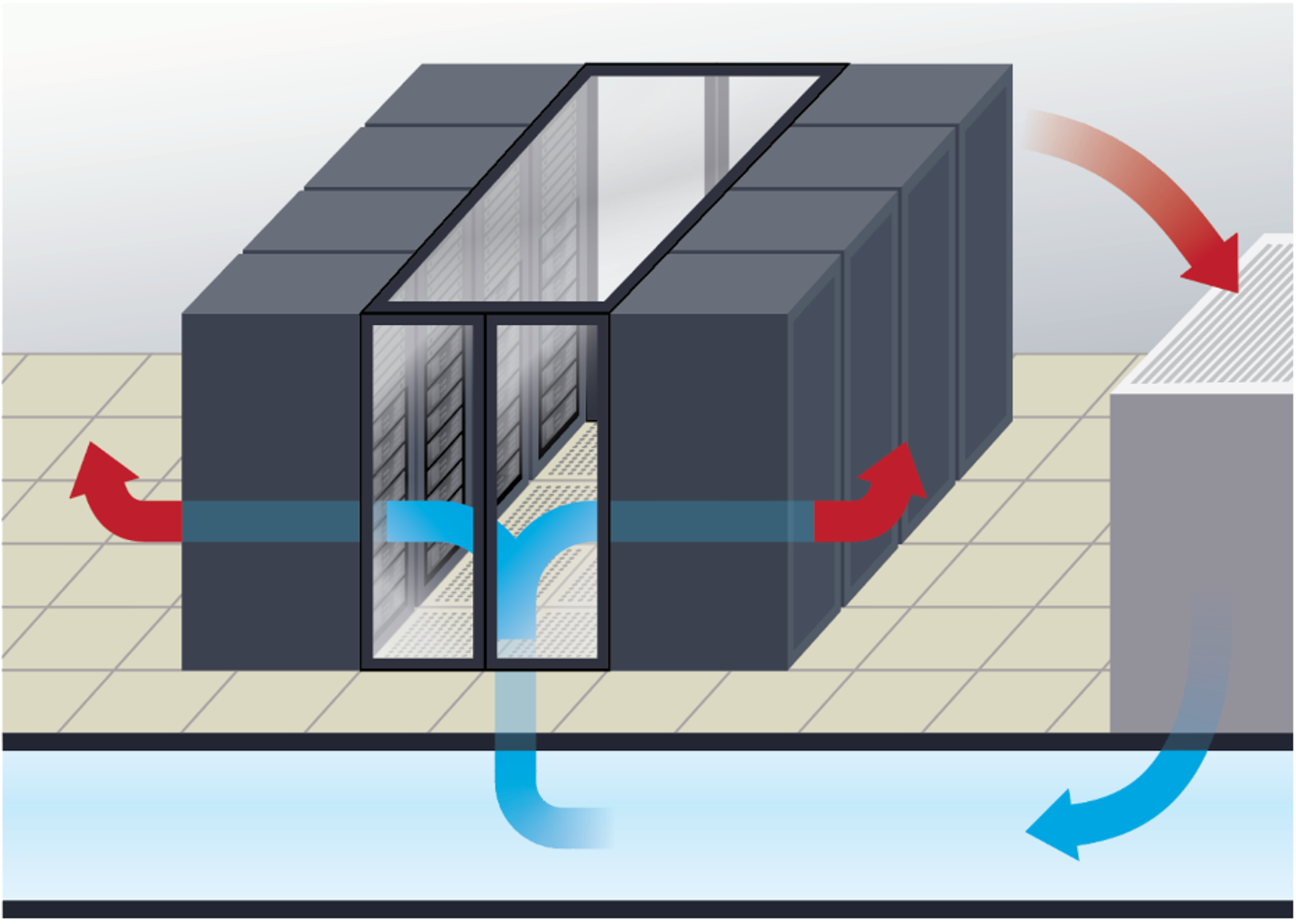

Figure 3 shows the fundamentals of cold aisle containment. When cold aisle containment is implemented, the remainder of the room is occupied by exhaust air and if this strategy is deployed effectively the rest of the room will be very hot. Cold aisle containment can also be done with overhead supply, in this case ducts would deliver the conditioned air to the cold aisle from above. Cold aisle containment with overhead supply is common with a slab environment.

Figure 3: Full cold aisle containment

In some cases, partial cold aisle containment is all that’s necessary for achieving a highly efficient cooling infrastructure. The angled baffles above the cold aisle in Figure 4 block the flow of exhaust air over the tops of cabinets and help retain the conditioned air in the cold aisle.

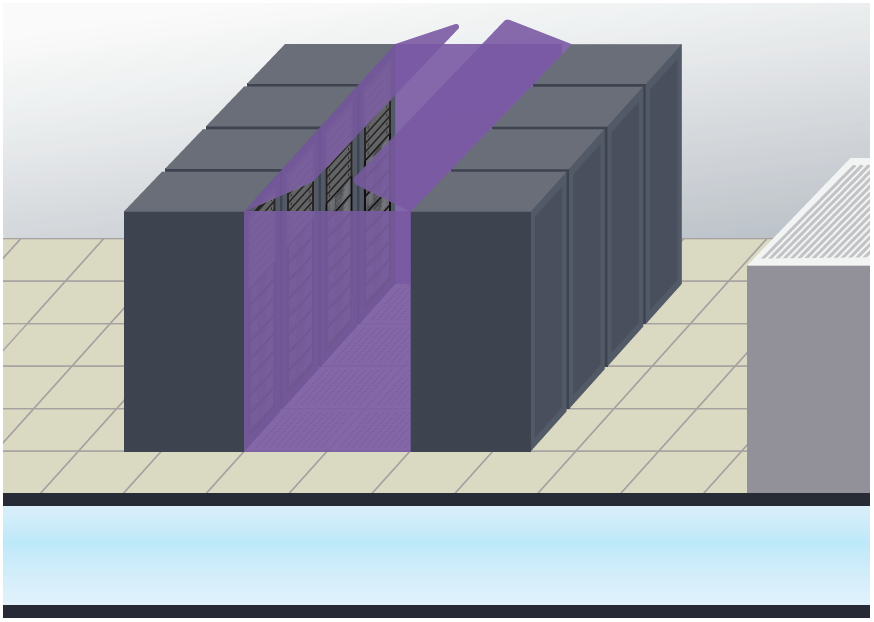

Figure 4: Partial cold aisle containment

Expert Advice

Full containment is aisle-end doors and a full roof over the aisles, while partial containment is aisle-end doors with baffles over the tops of cabinets. Partial containment is nearly as effective as full containment but is often more cost-effective with a quicker return on investment. In addition, adding aisle-end doors is far more beneficial than sealing over the tops of the cabinets.

After making AFM improvements at the Row level, it is important to make adjustments to cooling unit controls at the Room level to optimize the cooling infrastructure and realize energy savings. This is referred to as cooling optimization.

Featured Resources

- [Blog] What You Need to Know About Row Airflow Management

- [Video] The Lesser Known Row Airflow Management Best Practices

- [Blog] Key Considerations When Implementing Hot Aisle vs. Cold Aisle Containment

- [Blog] Identifying the Best Conditions for Cold Air Containment

- [Blog] Identifying the Best Conditions for Hot Air Containment

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

0 Comments