Grommets: The Foundation of Cooling Efficiency in Raised Floor Data Centers9 min read

Maintaining the cooling efficiency in any data center is an iterative process with many moving parts. It begins with the purchase and installation of cooling units, and is inevitably met with the implementation and continuous mediation of airflow management (AFM) best practices. There are a variety of AFM best practices including, but not limited to hot & cold aisle separation, blanking panel utilization, perforated tile placement, and many more that enable the lowering of fan speeds and/or increasing of temperature set points. However, when it comes to the basics of airflow management, grommets stand at the foundation of these improvements in raised floor data centers.

Why Grommets?

Many data centers have raised floors which are used for air distribution to efficiently disperse conditioned air into the cold aisles. Coupled with that, perforated tiles and/or directional grates are placed in the cold aisles in order to direct the conditioned air to the IT equipment. Managing the placement of these perforated tiles and grates is a common best practice and should be the first step to proper airflow management at the raised floor level. By itself, it is a great start to maintaining a computer room’s cooling efficiency; however, it is only the start. Upsite has found that on average 48% of a computer room’s cooling capacity escapes through unsealed cable openings in the raised floor. The easiest and most effective way to combat the leakage of conditioned air through cable openings is by using grommets.

Benefits of Raised Floor Grommets

The main purpose of grommets are to block airflow through cable cutouts, however there are additional benefits that can be realized by using grommets in your data center:

Bypass airflow is any conditioned air supplied by a cooling unit that does not pass through IT equipment before returning to a cooling unit. The ideal for airflow in a computer room is for every molecule of conditioned air supplied by cooling units to pass through IT equipment just once before returning to a cooling unit.

Installing grommets can increase the volume of conditioned airflow available to the areas most challenged by the increasing heat densities of new equipment. Additionally, the sealing of these open spaces allows for more pressure under the raised floor increasing the volume of conditioned air travelling through the IT equipment.

Cooling units are often installed to combat inefficient cooling of IT equipment, however inefficient cooling is often caused for other reasons. If conditioned air is escaping through cable cutouts it can pre-cool the exhaust air returning to the unit reducing the return air temperature which in turn reduces the delivered or sensible capacity of a cooling unit by more than 10 percent. It can also increase latent cooling which wastes energy by removing moisture instead of reducing temperature.

With the installation of grommets, many changes can be made to improve the efficiency of the cooling units. The increase of conditioned air moving through the IT equipment allows data center managers to raise temperature set points, reduce fan speeds, and even use less cooling units. Additionally the cooling equipment’s lifespan is expanded.

Savings can be made with improvement of airflow by using grommets. They can result in making the data center have a lower risk of any heat related damage that can result in extensive maintenance, outages, and information blackouts. Additionally, with raised temperature set points, reduced fan speeds, and less cooling units there can be significant drops in costs for electricity, property taxes, and maintenance.

How Grommet Choice Can Impact Potential Savings

Are all brush grommets created equal? And how does the choice of grommet impact savings over the long run?

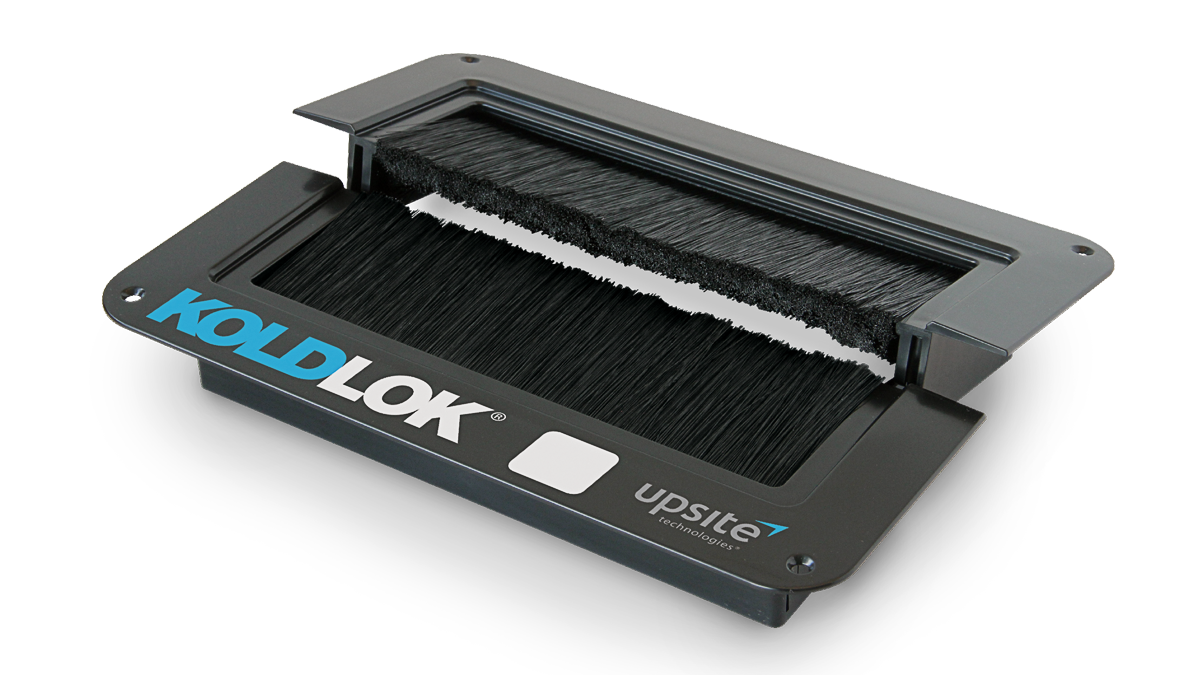

A recent report published in ASHRAE®’s technical library examines these exact questions. The report contains the results of testing sealing effectiveness for 5 leading brands of brush grommets: KoldLok, CoolBalance, Air-Guard, Mink Bursten, and Air-Lokk. The results showed a significant difference in the sealing capability of each brand.

While all grommets in the test offered some savings benefits, KoldLok offered 48% more savings than the next-best competitor, illustrating how the choice in grommet can impact savings over the long run. KoldLok’s superior sealing capability—made possible by its dual-layer brush design—ultimately makes KoldLok the most economical grommet choice with its long-term savings capability.

Airflow Management Awareness Month

Free Informative webinars every Tuesday in June.

0 Comments