The Importance of Sealing Rack Gaps in Your Data Center17 min read

For those of you who may not be familiar with the term “rack gap”, this refers to any opening or space between data center equipment racks. While it may seem like an understatement to say that sealing these gaps is an important aspect of airflow management, it is not uncommon to see rack gaps go unsealed. If not addressed, rack gaps can dramatically compromise your data center cooling and airflow management strategy.

Before we jump into the importance of sealing rack gaps, it’s important to understand why they occur in the first place. The two most common reasons are either because a building column is present in an aisle, or because a cabinet has been removed to be replaced at a later time. The former typically results in two small gaps (one on either side of the column), while the latter will result in one large rack gap. Keep in mind, a missing cabinet at the end of an aisle is also considered a rack gap and will not only result in a large gap but also uneven aisle lengths that could prevent the installation of containment doors. (To remediate this, a mounting post is often necessary to serve as a structural support.) Lastly, small rack gaps (.05” – 2”) could be present for many reasons (such as to allow for cable access), but can be easily addressed with sealing foam/tape. Nonetheless, rack gaps of all widths could wreak havoc in your data center and counteract other airflow management initiatives that have been implemented.

The Importance of Sealing Rack Gaps

Sealing the gaps between racks is extremely important for two reasons, as both of these conditions results in higher operating expenses wasted cooling capacity, as well as limited efficiency.

Reason 1: Exhaust air can flow into the cold aisle. Exhaust air recirculation into the cold aisle increases intake temperatures to IT equipment, which reduces your equipment’s reliability. This effect of exhaust air mixing with supply air and increasing intake temperatures (common to most data centers) requires more cooling units to be running or fan speeds to be higher than would otherwise be necessary. It also necessitates lower cooling unit temperature set points to overcome the mixing and keep your IT equipment intake air temperature within desired limits.

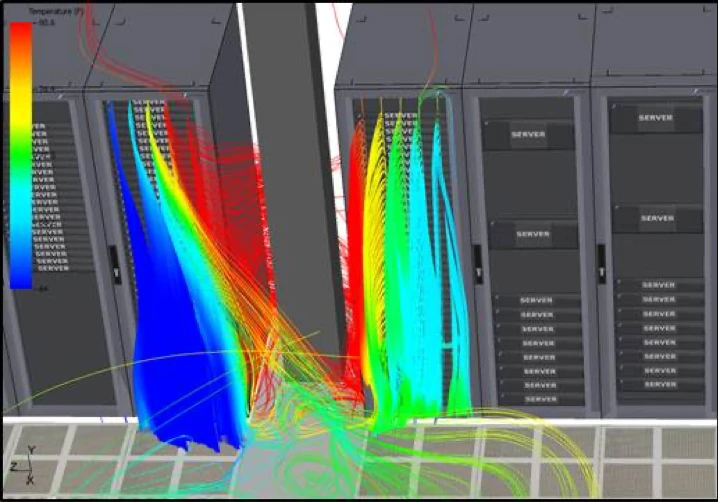

Before: Open Rack Gap

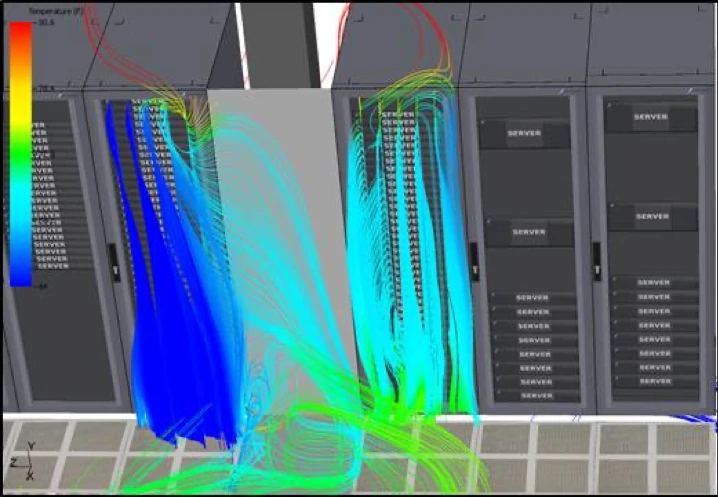

CFD analysis clearly shows how the rack gap allows for a large amount of exhaust air to recirculate. Airflow marked in red is outside of ASHRAE’s recommended input temperature range. Installing a rack gap panel dropped the maximum IT inlet temperature for the rack to the left of the column from 87.5°F to 76°F.

After: Sealed Rack Gap

Reason 2: Large volume of conditioned air can be lost. Similar to exhaust air entering the cold aisle, the loss of conditioned supply air requires more cooling units to be running or higher fan speeds to overcome the loss of conditioned airflow volume.

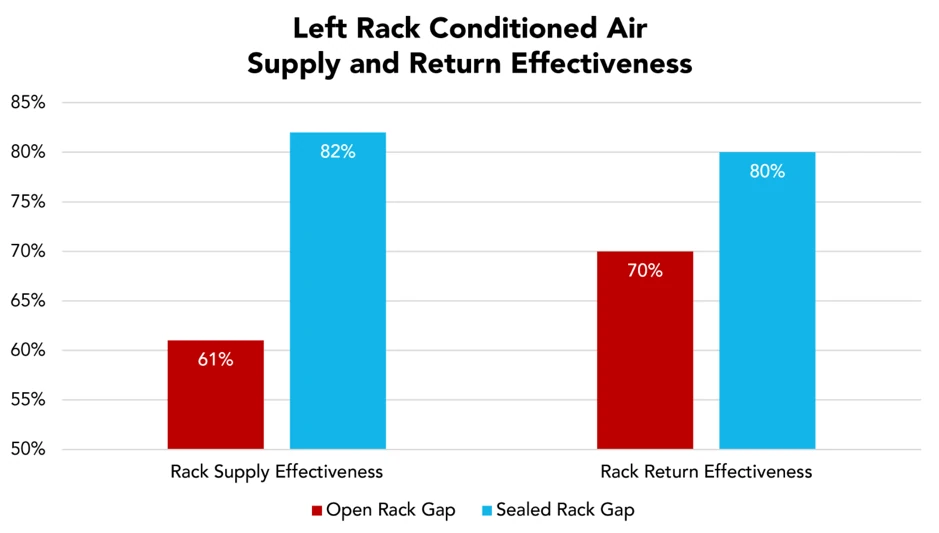

Additionally, the rack supply effectiveness suffers. This is the percentage of air entering the rack directly from a cooling unit, without mixing with hot air first (a higher percentage here is better). Rack return effectiveness also drops, which is the percentage of hot exhaust air leaving the rack that travels directly back to a cooling unit without first mixing with cold supply air (a higher percentage here is better).

In our CFD analysis, we closely examined the left rack (as seen in above CFD image) and quantified the impact that sealing rack gaps has on these two metrics. As you can see, sealing the gap greatly increases both the rack supply effectiveness, as well as the rack return effectiveness.

Conclusion

When implementing an airflow management strategy, the goal is usually to improve the intake air temperatures to IT equipment. More specifically, to reduce the highest intake air temperatures so that all intake temperatures are as low and even as possible. This, in return, enables changing the control of cooling infrastructure to improve efficiency and increase capacity. While many people make an effort to seal openings within the rack, such as open U spaces, gaps between the racks are commonly overlooked. These “rack gaps” are generally much larger openings and can dramatically compromise your data center cooling and airflow management strategy if they are not properly addressed.

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

The industry's easiest to install containment!

AisleLok® solutions are designed to enhance airflow management,

improve cooling efficiency and reduce energy costs.

0 Comments